Transmission Line Pipe is a fundamental element in contemporary energy networks, providing a robust pathway for oil, gas, and other fluids. Engineered to comply with API 5L standards, these pipes combine superior strength, resistance to corrosion, and long-lasting durability. The X70 steel grade delivers exceptional toughness and tensile strength, making Transmission Line Pipe indispensable for pipelines in challenging terrains and high-pressure environments.

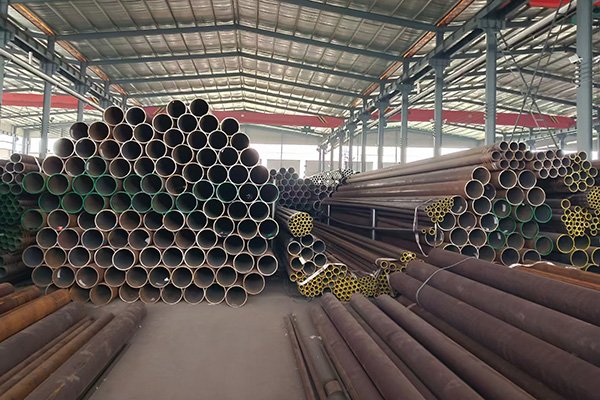

Working with a China manufacturer that offers verified bulk supply proof ensures uninterrupted delivery, compliance with international regulations, and reliable project execution, establishing Transmission Line Pipe as a dependable choice for critical energy infrastructure.

How Transmission Line Pipe is Manufactured

Piercing and Hot Rolling

Production begins with solid steel billets that are pierced and hot-rolled into hollow tubes. This seamless process removes longitudinal welds, producing uniform wall thickness and consistent mechanical properties.

Extrusion and Diameter Control

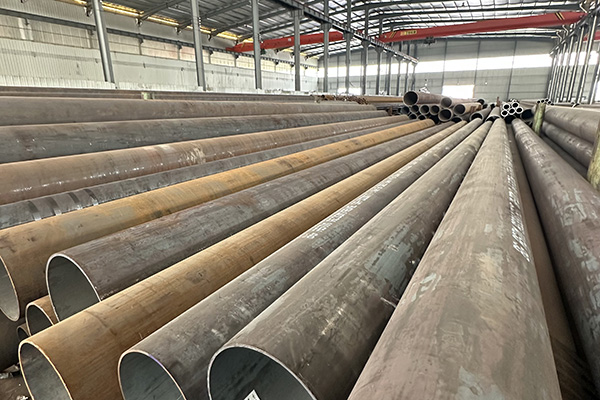

The hollow tubes are further extruded and stretch-reduced to achieve precise diameters and wall thicknesses. This step guarantees dimensional accuracy, enhanced strength, and high-pressure tolerance.

Heat Treatment and Stress Relief

Pipes are subjected to controlled heat treatment to reduce internal stresses and improve microstructural characteristics. This process enhances toughness, ductility, and long-term performance under demanding operating conditions.

Inspection and Protective Coating

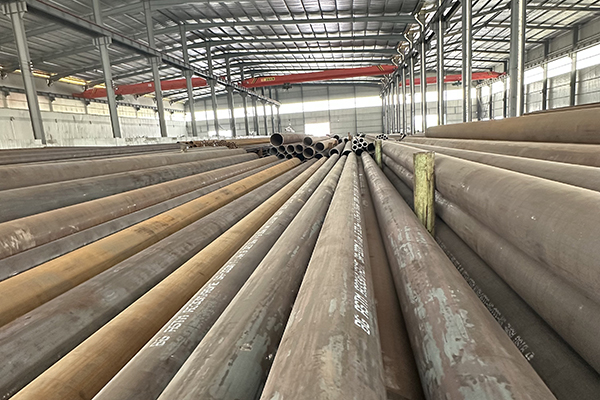

Each pipe undergoes strict inspection for dimensional compliance, mechanical properties, and surface integrity. Protective coatings, such as epoxy or polyethylene, are applied to enhance corrosion resistance in harsh environments.

Advantages of Transmission Line Pipe

Exceptional Strength and Pressure Handling

Without longitudinal welds, Transmission Line Pipe withstands higher internal pressures and external loads. The API 5L X70 grade offers the tensile strength required for safe long-distance transport of oil, gas, and industrial fluids.

Long-Term Durability

Uniform wall thickness and a high-quality steel microstructure minimize fatigue, cracking, and environmental degradation, extending service life in offshore, desert, and mountainous installations.

Enhanced Operational Safety

Seamless construction reduces potential weak points, decreasing the likelihood of pipeline failures. API 5L X70 Transmission Line Pipe provides dependable performance under extreme operational conditions.

Industrial Applications

Oil and Gas Transport

Transmission Line Pipe is essential for long-distance pipelines, ensuring safe transport of hydrocarbons across challenging terrains and between countries.

Petrochemical and Industrial Facilities

High-strength X70 pipes handle corrosive chemicals and high-temperature fluids, making them suitable for chemical plants, refineries, and other industrial applications.

Renewable and Thermal Energy Systems

Transmission Line Pipe also serves in hydroelectric and thermal power systems, acting as high-pressure conduits for water, steam, and other fluids crucial to energy generation.

Standards and Material Specifications

API 5L Compliance

The API 5L standard establishes stringent guidelines for chemical composition, mechanical properties, and testing requirements, ensuring that Transmission Line Pipe meets global energy infrastructure standards.

X70 Steel Grade

The X70 grade combines high yield strength, toughness, and weldability. It conforms to API 5L PSL2 specifications, making it ideal for pipelines that face high pressure and extreme environmental conditions.

Why Choose a China Manufacturer

Bulk Supply and Project Reliability

Large-scale energy projects demand substantial volumes of Transmission Line Pipe. Partnering with a China supplier providing verified bulk supply proof ensures timely delivery, consistent quality, and smooth project implementation.

Competitive Pricing and Custom Solutions

China manufacturers offer cost-effective options while adhering to API 5L standards. They can provide customized pipe diameters, wall thicknesses, and coating options tailored to project specifications.

Quality Assurance and Documentation

Reliable suppliers issue mill test certificates, inspection reports, and compliance documentation, reducing procurement risks and providing traceability for every batch.

Practical Considerations

·Material Verification – Ensure API 5L X70 pipes meet project-specific pressure, temperature, and environmental requirements.

·Transport and Storage – Protect pipes during shipment and storage to prevent coating or surface damage.

·Third-Party Testing – Independent inspections verify compliance and quality.

·Maintenance Planning – Routine monitoring and corrosion protection extend operational lifespan.

Conclusion

Transmission Line Pipe is a crucial component for modern energy infrastructure, delivering reliability, durability, and safety. Manufactured to API 5L standards using X70 steel, these pipes provide consistent performance for high-pressure and challenging applications.

Sourcing from a China manufacturer with bulk supply proof ensures steady delivery, verified quality, and international compliance. For energy projects demanding long-term reliability and operational safety, Transmission Line Pipe remains an essential solution.

References

GB/T 7714:Costa L M T, De Melo G N, Castro N A, et al. Microstructural characterization of API 5L X65 and X70 steels manufactured by TMCP process[J]. Tecnologia em Metalurgia, Materiais e Mineração, 2022, 19: 0-0.

MLA:Costa, Luan Mayk Tôrres, et al. "Microstructural characterization of API 5L X65 and X70 steels manufactured by TMCP process." Tecnologia em Metalurgia, Materiais e Mineração 19 (2022): 0-0.

APA:Costa, L. M. T., De Melo, G. N., Castro, N. A., & de Almeida Buschinelli, A. J. (2022). Microstructural characterization of API 5L X65 and X70 steels manufactured by TMCP process. Tecnologia em Metalurgia, Materiais e Mineração, 19, 0-0.