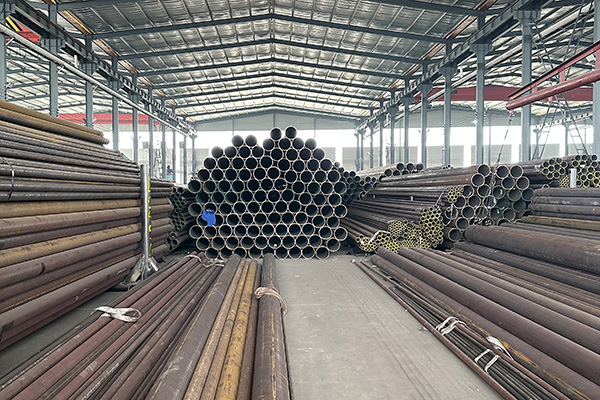

For global industrial projects—from oil and gas transmission to power generation and construction—choosing the right piping solution means prioritizing compliance, performance, and versatility. ASTM carbon steel pipe stands as the gold standard for reliability, with seamless and welded variants designed to meet the diverse needs of industrial applications worldwide. ASTM (American Society for Testing and Materials) standards ensure consistent quality, dimensional precision, and mechanical performance, making these pipes the top choice for engineers, project managers, and contractors across continents. Whether your project requires the high-pressure resistance of seamless ASTM carbon steel pipe or the cost-efficiency of welded options, our comprehensive range delivers tailored solutions that align with global industrial norms, ensuring seamless integration and long-term durability.

Why ASTM Carbon Steel Pipe? The Global Standard for Industrial Reliability

ASTM standards are universally recognized for their rigorous requirements, setting benchmarks for carbon steel pipe quality, composition, and performance. When you choose ASTM carbon steel pipe—whether seamless or welded—you’re investing in a product that meets the strictest industry criteria, making it suitable for global industrial projects of all scales:

Global Compliance & Interoperability: ASTM standards (such as ASTM A106, ASTM A53) are adopted worldwide, ensuring that your carbon steel pipe is compatible with international project specifications, regardless of location. This eliminates compatibility risks and simplifies cross-border procurement and installation.

Consistent Quality & Performance: ASTM standards mandate strict controls over chemical composition, tensile strength, yield strength, and dimensional accuracy. This consistency guarantees that every pipe performs reliably, even in harsh industrial environments—from high-temperature steam lines to low-pressure fluid distribution.

Versatility in Form & Function: ASTM carbon steel pipe is available in two primary variants—seamless and welded—each engineered to address specific project needs. Seamless pipes excel in high-pressure, high-temperature applications, while welded options offer cost-efficiency for large-scale, low-to-medium pressure projects.

Cost-Effective Durability: ASTM carbon steel pipe balances affordability with longevity, delivering a low total cost of ownership. Its inherent durability resists wear, fatigue, and corrosion (with optional treatments), reducing maintenance and replacement costs over the pipe’s service life.

ASTM Carbon Steel Pipe: Seamless vs. Welded—What’s the Difference?

The two core variants of ASTM carbon steel pipe—seamless and welded—differ in manufacturing process, mechanical properties, and ideal applications. Understanding their unique characteristics helps you select the perfect option for your global industrial project, ensuring optimal performance and cost-efficiency:

1. Seamless ASTM Carbon Steel Pipe: High-Pressure, High-Performance

Seamless ASTM carbon steel pipe is manufactured by heating a solid steel billet and piercing it to form a hollow tube, with no weld seams. This seamless structure eliminates weak points, making it ideal for high-pressure, high-temperature industrial applications where reliability is non-negotiable[3]. The production process involves precise heating (up to 1250±20℃) and piercing, followed by rolling and heat treatment to ensure uniform structure and mechanical properties[1].

·Key Advantages: Exceptional pressure resistance (no weld seams to fail), dimensional precision (tighter tolerances), and superior mechanical strength. Suitable for extreme temperatures and high-stress environments. For example, ASTM A106 Grade C seamless pipe undergoes controlled heat treatment to achieve tensile strength ≥415MPa and yield strength ≥240MPa, with excellent high-temperature stability[1].

·Manufacturing Highlights: Produced via hot rolling or cold drawing processes. Hot-rolled seamless pipes are formed by heating billets and piercing them with a mandrel, while cold-drawn variants undergo additional processing to achieve finer dimensional accuracy (wall thickness偏差 ≤±0.1mm for thin-walled pipes)[1][4]. Heat treatment (normalizing, tempering) is critical to optimize grain structure and enhance performance[1].

·Ideal Applications: High-pressure steam pipelines in power plants, refinery fluid lines, oil and gas well casings, and chemical plant high-pressure systems—projects where failure is not an option.

2. Welded ASTM Carbon Steel Pipe: Cost-Efficient & Scalable

Welded ASTM carbon steel pipe is manufactured by bending flat steel plates or coils into a cylindrical shape and welding the longitudinal seam using methods like Electric Resistance Welding (ERW) or Submerged Arc Welding (SAW)[3]. This process is more cost-effective than seamless production, making welded pipes ideal for large-scale, low-to-medium pressure industrial projects where budget efficiency is key.

·Key Advantages: Lower production costs compared to seamless pipes, availability in larger diameters, and faster production lead times. Welded seams are rigorously tested to meet ASTM standards, ensuring reliability for medium-pressure applications. ERW welded pipes, for example, offer consistent seam quality with minimal defects[3].

·Manufacturing Highlights: ERW welding uses electric current to fuse the steel edges without additional filler material, creating a strong, uniform seam. SAW welding is used for thicker-walled pipes, providing deeper weld penetration. Post-weld heat treatment (PWHT) is often applied to reduce residual stress and improve seam strength[1].

·Ideal Applications: Water and gas distribution pipelines, construction structural supports, industrial fluid lines (low-to-medium pressure), and large-diameter infrastructure projects—applications where cost-efficiency and scalability are prioritized.

Top ASTM Carbon Steel Pipe Models: Seamless & Welded

We offer a comprehensive range of ASTM carbon steel pipe, covering the most widely used seamless and welded models for global industrial projects. Each model adheres to strict ASTM standards, with detailed specifications tailored to specific applications:

Seamless ASTM Carbon Steel Pipe Models

·ASTM A106 Grade B: The most popular seamless ASTM carbon steel pipe for high-temperature (up to 454℃) and high-pressure applications. Tensile strength ≥415MPa, yield strength ≥241MPa, with an outside diameter (OD) range of 6.4mm to 1016mm and wall thickness (WT) of 0.4mm to 50mm. Ideal for power plant steam pipelines, refineries, and high-pressure fluid transport[1].

·ASTM A106 Grade C: A higher-strength seamless variant, with tensile strength ≥485MPa and yield strength ≥276MPa. Designed for more demanding high-temperature, high-pressure industrial applications, such as supercritical power plant pipelines. Its carbon content is controlled ≤0.35%, with manganese content 0.29-1.06% for enhanced mechanical performance[1].

·ASTM A333 Grade 6: Seamless low-temperature carbon steel pipe, capable of withstanding temperatures as low as -45℃. Tensile strength ≥415MPa, yield strength ≥241MPa, making it ideal for cryogenic industrial projects (LNG transport, cold water pipelines) worldwide.

Welded ASTM Carbon Steel Pipe Models

·ASTM A53 Grade B: The most versatile welded (ERW and seamless optional) ASTM carbon steel pipe, suitable for low-to-medium pressure applications. Tensile strength ≥415MPa, yield strength ≥240MPa, OD range of 10.3mm to 1200mm, WT of 1.0mm to 150mm. Used for water/gas distribution, industrial fluid lines, and construction[4].

·ASTM A53 Grade A: A cost-effective welded variant with tensile strength ≥331MPa, yield strength ≥186MPa. Ideal for low-pressure industrial applications where performance requirements are moderate, such as non-critical fluid transport and structural supports.

Key Specifications of ASTM Carbon Steel Pipe (Seamless & Welded)

Our ASTM carbon steel pipes—both seamless and welded—are available in flexible specifications to fit the unique needs of global industrial projects, with strict adherence to ASTM standards:

·Outside Diameter (OD): 6.4mm to 1200mm (seamless); 10.3mm to 1200mm (welded)

·Wall Thickness (WT): 0.4mm to 50mm (seamless); 1.0mm to 150mm (welded). Seamless pipes offer tighter thickness tolerance (±5%) compared to welded options (±8%)[1][3].

·Tensile Strength: 331MPa to 485MPa (varies by model and grade). ASTM A106 Grade C offers the highest tensile strength among common models[1].

·Yield Strength: 186MPa to 276MPa (varies by model and grade)

·Operating Temperature: -45℃ to 454℃ (varies by model). ASTM A333 Grade 6 excels in low-temperature environments, while ASTM A106 grades perform well at high temperatures[1].

·Welding Compatibility: All models are easy to weld, with ASTM A106 Grade B/C offering excellent weldability for on-site fabrication[1].

·Standards Compliance: Full compliance with ASTM A106, ASTM A53, ASTM A333, with certification available (EN 10204 3.1, ASTM test reports) for global project verification.

·Quality Testing: Rigorous non-destructive testing (ultrasonic, eddy current) ensures defect detection rates up to 99.6%[1]. Additional tests include tensile strength, yield strength, and hydrostatic pressure testing (1.5x maximum working pressure).

References

GB/T 7714: ASTM A106/A106M-23: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service. ASTM International Standards Journal

MLA:ASTM A53/A53M-22: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. ASTM International Standards Journal

APA:Mechanical Performance of ASTM A106 Grade C Seamless Carbon Steel Pipe in High-Temperature Industrial Applications. Journal of Thermal Power Generation