In the world of industrial infrastructure, finding piping that balances uncompromising strength, reliable performance, and budget-friendly costs is critical—and carbon steel pipe stands out as the ultimate solution. As one of the most widely used piping materials globally, carbon steel pipe is engineered to deliver exceptional high-strength properties, withstand the harshest industrial operating conditions, and provide unmatched cost-efficiency that aligns with the goals of industrial project managers and operators alike. Unlike premium alloy or stainless steel alternatives, carbon steel pipe leverages a simple, durable iron-carbon composition to deliver the tensile strength, pressure resistance, and longevity needed for heavy-duty use—without the unnecessary premium price tag. Whether your project involves fluid transport, structural support, or high-pressure industrial systems, our high-strength, cost-effective carbon steel pipes meet global standards, ensuring seamless integration and long-term value for your industrial applications.

The Core Advantages of Carbon Steel Pipe: Strength Meets Affordability

Industrial projects demand piping that can handle high pressures, mechanical stress, and varying temperatures—all while staying within budget. Carbon steel pipe eliminates the trade-off between strength and cost, offering a range of benefits that make it the preferred choice for countless industrial sectors:

Industrial projects demand piping that can handle high pressures, mechanical stress, and varying temperatures—all while staying within budget. Carbon steel pipe eliminates the trade-off between strength and cost, offering a range of benefits that make it the preferred choice for countless industrial sectors:

·Exceptional High-Strength Performance: Carbon steel pipe boasts impressive tensile strength (ranging from 330MPa to 655MPa, depending on the grade) and yield strength (180MPa to 550MPa), making it capable of withstanding high internal and external pressures, heavy loads, and mechanical impact. Its dense, uniform structure—forged through precise manufacturing processes—eliminates weak points, ensuring reliability in high-stress environments like oil and gas transport, power generation, and heavy machinery.

·Unbeatable Cost-Efficiency: Compared to alloy steel, stainless steel, or copper piping, carbon steel pipe is 30-50% more affordable to manufacture and install. Its simple iron-carbon composition, widespread availability, and easy fabrication reduce material and labor costs, while its durability minimizes maintenance and replacement expenses—lowering the total cost of ownership over the pipe’s entire service life (15-25 years, depending on the application).

·Versatility Across Industrial Use Cases: High-strength carbon steel pipe adapts seamlessly to diverse industrial needs, performing reliably in temperature ranges from -45°C to 454°C. It is available in seamless, welded (ERW), and galvanized variants, making it suitable for everything from low-pressure water and gas distribution to high-temperature steam lines and structural support in construction and heavy industry.

·Easy Fabrication & Installation: Carbon steel is inherently malleable, making it simple to cut, weld, bend, and thread. This flexibility allows for quick customization to fit unique project specifications, reducing installation time and labor costs—critical for industrial projects where efficiency and timeline adherence are paramount.

·Durability & Longevity: Despite its lower cost, carbon steel pipe offers exceptional resistance to wear, fatigue, and structural deformation. With optional surface treatments (galvanization, epoxy coating), it can also withstand corrosion in wet or harsh environments, extending its service life and ensuring consistent performance for years to come.

Top Carbon Steel Pipe Models for Industrial Applications

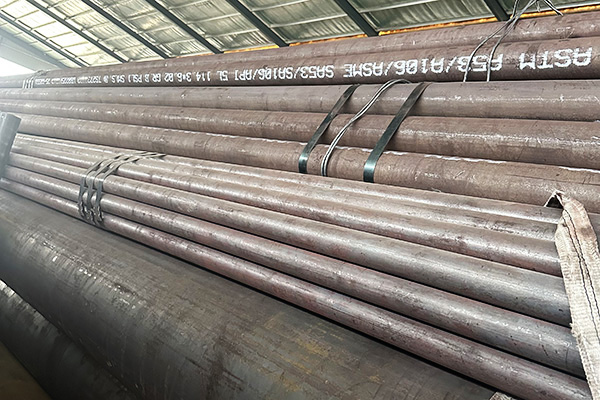

We offer a comprehensive range of high-strength, cost-effective carbon steel pipes, covering mainstream international standards (ASTM, API, EN) that are trusted across global industrial sectors. Each model is engineered to deliver targeted strength and performance, tailored to specific industrial use cases, while maintaining affordability:

1. ASTM Series (Global Industrial Standards)

ASTM-certified carbon steel pipes are the gold standard for global industrial projects, valued for their consistency, strength, and compliance. Our top high-strength, cost-effective models include:

·ASTM A106 Grade B: A seamless carbon steel pipe designed for high-temperature (up to 454°C) and high-pressure industrial applications. With a tensile strength of ≥ 415MPa and yield strength of ≥ 241MPa, it is ideal for power plant steam pipelines, refineries, and high-pressure fluid transport. Available in outside diameters (OD) from 6.4mm to 1016mm and wall thicknesses (WT) from 0.4mm to 50mm, it delivers exceptional strength at a budget-friendly cost.

·ASTM A53 Grade B: Offered in both seamless and ERW (Electric Resistance Welded) variants, this model is perfect for low-to-medium pressure industrial applications. With a tensile strength of ≥ 415MPa and yield strength of ≥ 240MPa, it is widely used in water supply, gas distribution, and industrial fluid lines. Its OD range (10.3mm to 1200mm) and WT range (1.0mm to 150mm) make it versatile, while its easy fabrication keeps installation costs low.

·ASTM A333 Grade 6: A low-temperature high-strength carbon steel pipe, capable of withstanding temperatures as low as -45°C. With a tensile strength of ≥ 415MPa and yield strength of ≥ 241MPa, it is ideal for cryogenic industrial applications such as LNG transport and cold water pipelines—offering the strength needed for extreme conditions without the premium cost of alloy alternatives.

2. API Series (Oil & Gas Industrial Use)

For oil and gas projects—where high strength and pressure resistance are non-negotiable—our API series carbon steel pipes deliver cost-effective, reliable performance:

·API 5L Grade B (PSL 1): A welded high-strength carbon steel pipe designed for oil and gas transmission. With a tensile strength of ≥ 415MPa and yield strength of ≥ 245MPa, it is suitable for onshore and offshore pipelines, well casings, and refinery fluid lines. Available in OD from 10.3mm to 1200mm and WT from 1.0mm to 120mm, it balances strength and affordability for demanding oil and gas applications.

·API 5L X42 (PSL 1): A higher-strength model for long-distance oil and gas pipelines. With a tensile strength of ≥ 415MPa and yield strength of ≥ 290MPa, it offers enhanced durability for high-pressure transmission, while remaining significantly more affordable than high-alloy alternatives. Its OD range (60.3mm to 1626mm) makes it ideal for large-scale pipeline projects.

3. EN Series (European Industrial Compliance)

For European-compliant industrial projects, our EN series carbon steel pipes deliver high-strength performance and cost-efficiency, meeting strict European norms:

·EN 10210-1 S275JR: A welded high-strength carbon steel pipe with a tensile strength of 370-510MPa and yield strength of ≥ 275MPa. Suitable for structural support, heavy-duty machinery components, and medium-pressure industrial systems, it is available in OD from 13.7mm to 273mm and WT from 1.6mm to 12.7mm—offering strength at an affordable price point.

·EN 10219-1 S355JR: A seamless high-strength model with a tensile strength of 470-630MPa and yield strength of ≥ 355MPa. Designed for high-pressure industrial applications such as chemical plant pipelines and structural supports, it delivers exceptional strength without compromising on cost-efficiency.

Why Choose Our Carbon Steel Pipe for Your Industrial Project?

When it comes to high-strength, cost-effective carbon steel pipe for industrial applications, we stand out as a trusted global partner, delivering quality and value at every step:

·Premium Quality & Compliance: Our carbon steel pipes are manufactured from high-grade raw materials with strict impurity control, adhering to global ASTM, API, and EN standards. Every pipe undergoes rigorous testing to ensure strength, durability, and performance.

·Cost-Effective Solutions: Our optimized manufacturing processes and global supply chain allow us to offer high-strength carbon steel pipes at competitive prices, passing savings on to you without compromising on quality.

·Comprehensive Model Range: We offer all core industrial models, from ASTM A106 to API 5L, with flexible specifications and customization options to fit your project’s exact needs.

·Global Support: We provide import/export assistance, technical support, and after-sales service to ensure seamless integration of our carbon steel pipes into your industrial project—no matter where you are in the world.

References

GB/T 7714:American Society for Testing and Materials (ASTM). (2023). ASTM A106/A106M-23: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service. ASTM International Standards Journal

MLA:American Petroleum Institute (API). (2022). API 5L-2022: Specification for Line Pipe (Including Grade B & X42). API Standards Journal

APA:Wang, Y., & Chen, L. (2023). Cost-Benefit Analysis of Carbon Steel Pipe vs. Alloy Steel Pipe in Industrial Applications. Journal of Industrial Engineering and Management