Maintenance and Care of Alloy Steel Pipes

Maintaining alloy steel pipes is essential to ensure long-term safety, operational efficiency, and resistance to damage caused by corrosion, mechanical stress, and temperature fluctuations. A well-structured maintenance program can significantly extend the service life of alloy steel pipes used in demanding environments such as oil and gas, chemical processing, power generation, and marine systems.

1. Regular Inspection and Monitoring

Routine inspections help detect early signs of degradation, leaks, or structural issues. Key inspection techniques include:

Ultrasonic testing (UT): Measures wall thickness to detect thinning due to internal or external corrosion.

Visual inspection: Checks for surface rust, discoloration, cracks, or deformation.

Magnetic particle testing and dye penetrant testing: Identify surface cracks or weld defects.

Pressure testing: Ensures pipeline integrity under operational conditions.

2. Cleaning and Surface Maintenance

Accumulated deposits, scale, or corrosion products can impair flow and promote localized damage. Maintenance includes:

Mechanical cleaning: Use of pipe pigs or brushes to remove debris.

Chemical cleaning: Circulating cleaning solutions to dissolve scale or internal corrosion.

Surface descaling and repainting: Especially for externally exposed pipes to prevent corrosion.

3. Corrosion Prevention

To protect against chemical or environmental corrosion:

External coatings and wraps: Such as epoxy or polyurethane layers to block moisture and chemicals.

Cathodic protection: For buried or underwater pipes, using sacrificial anodes or impressed current systems.

Corrosion inhibitors: Chemical additives introduced into the pipeline to reduce internal corrosion.

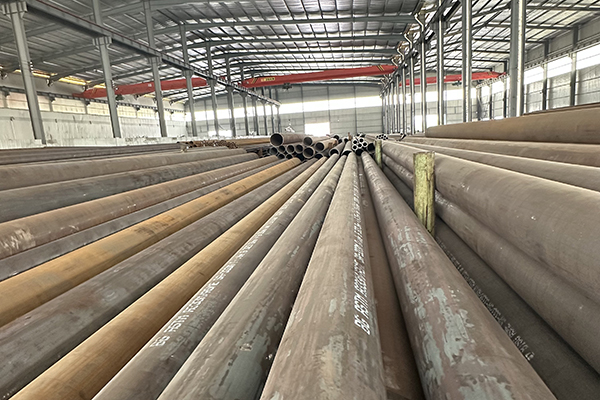

4. Proper Storage and Handling

Pipes should be stored in dry, well-ventilated areas away from direct contact with the ground or water. Use protective caps on pipe ends and avoid metal-to-metal contact that may cause scratches or dents.

5. Thermal Protection and Insulation

For pipes operating at high or fluctuating temperatures, thermal insulation reduces heat loss, controls surface temperature, and prevents thermal fatigue. Insulation materials must be dry, well-fitted, and resistant to weathering or oil absorption.

6. Stress Management and Support

Ensure that alloy steel pipes are properly supported and anchored to prevent sagging, vibration, and stress concentration. Use expansion joints or loops where necessary to accommodate thermal expansion.

7. Timely Repairs and Replacement

If any defects or corrosion are found, take immediate action:

Weld repairs for minor cracks or thinning areas

Pipe section replacement for severe corrosion or damage

Composite reinforcement wraps for temporary reinforcement under pressure

8. Documentation and Maintenance Records

Keep detailed logs of inspections, repairs, and test results. These records support predictive maintenance and compliance with industry regulations.

Conclusion

Proper maintenance and care of alloy steel pipes help reduce operational risks, enhance system reliability, and optimize lifecycle costs. A proactive, systematic approach is vital in high-demand industries where equipment failure can lead to serious safety, environmental, or economic consequences.

References:

API 570 – Piping Inspection Code

ASME B31.3 – Process Piping Code

NACE SP0169 – Control of External Corrosion on Underground or Submerged Metallic Piping Systems

ASM Handbook, Volume 13C – Corrosion: Environments and Industries

ISO 14723 – Guidelines for Integrity Management of Piping Systems