When industrial operators talk about transporting oil, natural gas, water, or other critical fluids over long distances, the term Line Pipe quickly becomes central to the conversation. Though often overlooked by beginners, Line Pipe is one of the most essential components in modern pipeline systems. It must endure extreme pressure, long-term exposure, and challenging environmental conditions. Understanding how Line Pipe works—and what differentiates one grade from another—is fundamental for anyone involved in pipeline engineering, procurement, or project planning.

This guide provides a complete yet beginner-friendly overview of Line Pipe, focusing on widely used API 5L standards and GR.B material. It also explains how manufacturing processes, large-scale Production capabilities, and batch supply capacity contribute to long-term reliability and cost efficiency.

What Exactly Is Line Pipe?

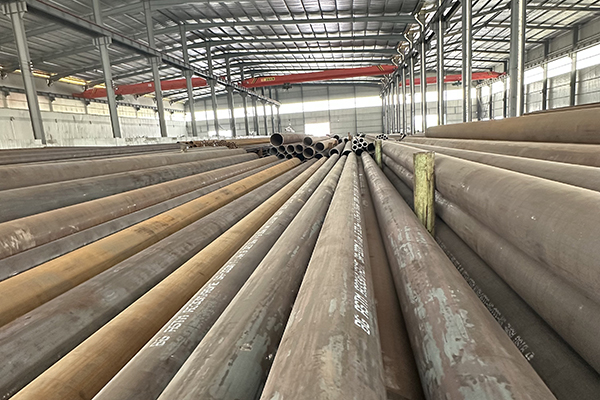

Line Pipe refers to tubular steel products specifically engineered to transport liquids, gases, and multiphase mixtures. Unlike standard structural steel pipes, Line Pipe is designed to withstand continuous pressure cycles, internal pressure variations, corrosion environments, and long-distance operational stresses.

Typical applications include:

·Oil and gas transmission

·Water and slurry pipelines

·Petrochemical transport

·Onshore and offshore pipeline systems

Because Line Pipe represents the backbone of national and international pipeline networks, it must meet strict quality and safety requirements defined by globally recognized standards.

Why API 5L Matters for Line Pipe

API 5L is the most recognized international specification for Line Pipe. It defines chemical composition, tensile strength, manufacturing tolerances, impact resistance, and pressure performance. For beginners, it helps to understand that API 5L ensures pipeline engineers receive a consistent, dependable product regardless of where the pipe is sourced.

Under API 5L, Line Pipe comes in multiple grades, among which GR.B is widely used due to its balance of weldability, strength, and cost-efficiency.

Key Characteristics of API 5L GR.B Line Pipe

·Moderate tensile strength suitable for medium-pressure pipelines

·Good weldability for long-distance pipeline construction

·Reliable toughness for general industrial service

·Predictable behavior during bending, coating, and installation

GR.B is often selected for water transport systems, low to medium-pressure natural gas lines, and general-purpose fluid transfer projects.

How Manufacturer-Level Production Influences Quality

Beginners often assume that all Line Pipe meeting API 5L specifications performs the same. In reality, the quality differences between suppliers can be significant. Pipes produced by a full-scale Manufacturer with modern Production technology demonstrate much higher uniformity and long-term durability.

The Impact of Advanced Production on Line Pipe Quality

A high-quality Manufacturer typically integrates:

·Precision-controlled rolling and forming

·Uniform heat treatment for consistent grain structure

·Automatic welding with real-time defect detection

·Ultrasonic, hydrostatic, and visual inspections

·Strict dimensional and mechanical property testing

These Production capabilities ensure the Line Pipe will maintain integrity under fluctuating pressures and environmental challenges.

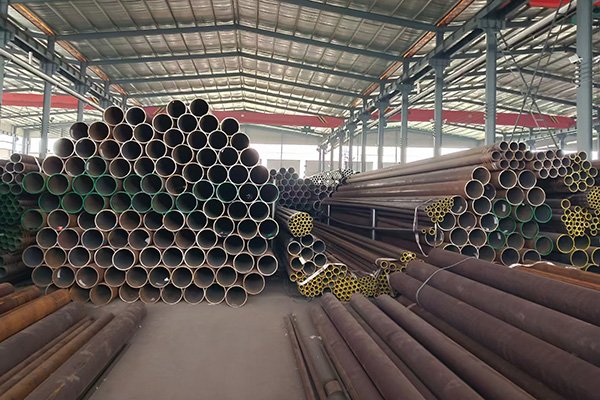

Manufacturers with strong batch supply capacity also offer advantages in large-scale projects, reducing delivery times and ensuring inventory consistency.

Why Material Grade and Manufacturing Method Both Matter

Line Pipe performance depends not only on grade (e.g., API 5L GR.B) but also on how the pipe is formed. Two common manufacturing methods include:

1. Seamless Line Pipe

Produced without welding, seamless Line Pipe is ideal for high-pressure and high-temperature service. It offers uniform strength and is often used in demanding oil and gas applications.

2. Welded Line Pipe

Welded Line Pipe, including ERW (Electric Resistance Welded) and LSAW (Longitudinal Submerged Arc Welded), supports large diameters and long lengths. When produced by a professional Manufacturer with automated welding lines, welded Line Pipe delivers exceptional performance at cost-efficient levels.

Both types, when manufactured under strict Production controls, meet API 5L requirements and deliver stable field performance.

How to Select the Right Line Pipe for a Project

Beginners should consider the following factors:

Internal Pressure and Design Conditions

Higher pressure systems may require thicker walls or higher grades.

Transported Medium

Corrosive fluids may require internal coatings or upgraded materials.

Pipeline Length and Installation Environment

Temperature swings, soil movement, or offshore conditions influence required toughness and pipe selection.

Manufacturer’s Production Capacity

A reliable Manufacturer with sufficient batch supply capability ensures:

·Consistent mechanical performance

·Predictable lead times

·Project-wide dimensional uniformity

·Controlled welding behavior during field installation

Certification Requirements

Pipes should carry proper API 5L markings, test results, and traceability documentation.

Why API 5L GR.B Remains Popular for Beginners

GR.B Line Pipe provides an ideal balance between material performance and cost. It works well for:

·Water transmission

·Municipal pipeline systems

·Low to medium-pressure oil and gas pipelines

·General industrial fluid transport

Because GR.B Line Pipe often comes from manufacturers with scalable Production lines, users benefit from both technical reliability and efficient batch supply.

Conclusion: Understanding Line Pipe Starts with Standards and Manufacturing

For anyone new to pipeline engineering or procurement, the journey begins with understanding what Line Pipe is and why API 5L standards—especially GR.B—play such an important role. Just as important is recognizing how Manufacturer-level Production and batch supply capability determine consistency, reliability, and suitability for large-scale projects.

Whether planning a new pipeline system or evaluating suppliers, keep these principles in mind. The right Line Pipe ensures safer operation, smoother installation, and long-term field performance—all essential for modern industrial infrastructure.

References

GB/T 7714:Bai Q, Bai Y. Subsea pipeline design, analysis, and installation[M]. gulf professional publishing, 2014.

MLA:Bai, Qiang, and Yong Bai. Subsea pipeline design, analysis, and installation. gulf professional publishing, 2014.

APA:Bai, Q., & Bai, Y. (2014). Subsea pipeline design, analysis, and installation. gulf professional publishing.