Introduction to Carbon Steel Seamless Pipe API 5L X56N

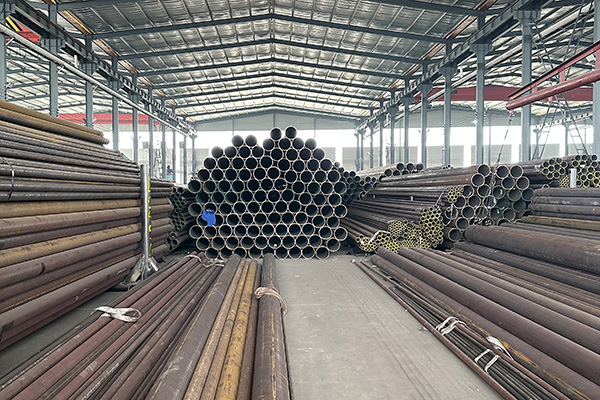

Carbon steel seamless pipes are widely used in the oil and gas industry for transportation of liquids and gases, especially in harsh conditions. Under the API 5L standard, carbon steel pipes come in various grades, and one of the most commonly used is API 5L X56N. But what makes this particular grade so valuable, and why are manufacturers and companies around the world opting for it?

In this article, we’ll explore what carbon steel seamless pipe under API 5L X56N is, its characteristics, applications, and how manufacturers ensure the highest quality in production.

What Is API 5L X56N?

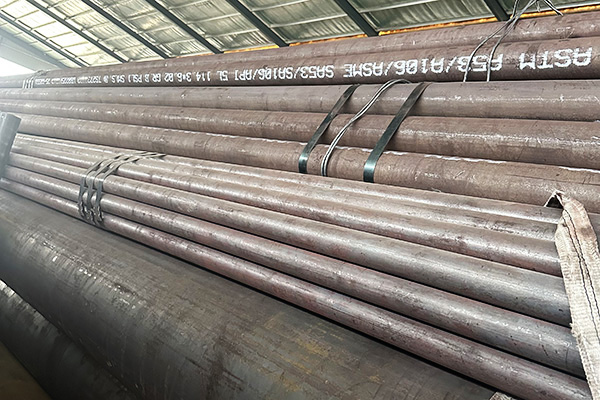

API 5L is a specification by the American Petroleum Institute (API) that covers the manufacturing and testing of steel pipes used for the transportation of oil and gas. The X56N grade refers to a specific classification of seamless pipes with a tensile strength range of 56,000 psi (approximately 380 MPa). The 'N' designation indicates that the steel pipe is normalized, which means it has been heat-treated to achieve specific mechanical properties for enhanced strength and durability.

Carbon steel seamless pipes under API 5L X56N are primarily designed for use in high-pressure, high-temperature environments, where strength, durability, and reliability are critical. They are often used in pipelines that carry oil, gas, and other fluids under extreme conditions.

Key Features of Carbon Steel Seamless Pipe API 5L X56N

1. High Strength and Durability

One of the standout features of API 5L X56N pipes is their high tensile strength. This makes them suitable for demanding applications like oil and gas pipelines, especially when exposed to harsh weather conditions, pressure, and temperature variations. The normalized treatment (denoted by 'N') further enhances the mechanical properties of the steel, ensuring better performance under stress.

2. Seamless Construction

Seamless pipes, as the name suggests, do not have any welded joints. This provides a significant advantage in applications that require pipes to withstand high internal pressure. The lack of a weld seam eliminates the risk of weak points, ensuring greater reliability and longer service life.

3. Corrosion Resistance

Carbon steel, while prone to corrosion, can be treated or coated to improve its resistance to rust and degradation over time. When API 5L X56N pipes are properly coated or treated, they exhibit excellent corrosion resistance, making them ideal for use in harsh, corrosive environments like offshore oil rigs or chemical processing plants.

4. Versatility in Application

The versatility of API 5L X56N pipes is evident in their widespread use across industries such as construction, petrochemicals, and offshore drilling. Whether in deep-sea oil exploration or onshore pipeline projects, these pipes offer the required strength and reliability.

Applications of Carbon Steel Seamless Pipe API 5L X56N

Oil and Gas Transportation

The primary use of carbon steel seamless pipes under API 5L X56N is for the transportation of oil and natural gas through pipelines. The high strength and seamless nature of the pipe ensure that it can withstand high-pressure environments and transport fluids over long distances without the risk of leaks or ruptures.

Construction and Infrastructure

API 5L X56N pipes are also used in the construction industry, particularly in the building of infrastructure like bridges, highways, and tunnels. The pipes' durability and resistance to wear and tear make them suitable for heavy-duty applications.

Industrial and Chemical Processing

Seamless pipes are essential in industries where high pressure and temperature are common. API 5L X56N pipes are used for transferring chemicals and other industrial fluids in processing plants, refineries, and chemical factories.

Manufacturing Process of Carbon Steel Seamless Pipe API 5L X56N

Manufacturing carbon steel seamless pipes under API 5L X56N involves several steps, each contributing to the pipe's final quality. The process begins with the creation of a billet or bloom, which is then heated and passed through a series of rollers to form the pipe shape. The pipe is then cooled, normalized, and tested to ensure it meets the required specifications.

Key steps in the manufacturing process:

1.Hot Rolling – The billet is heated to a specific temperature and passed through a set of rollers to form the pipe.

2.Normalization – The pipe is heated to a high temperature and then cooled to achieve the desired mechanical properties.

3.Quality Control and Testing – Every batch of pipes undergoes rigorous testing, including tensile strength tests, X-ray inspections, and pressure testing, to ensure compliance with the API 5L X56N standards.

Why Choose a Reliable Manufacturer for Carbon Steel Seamless Pipes?

When sourcing carbon steel seamless pipes under API 5L X56N, it's crucial to choose a manufacturer that adheres to the highest standards in production. A reputable manufacturer will ensure that the pipes are produced in line with API specifications, undergo comprehensive quality testing, and provide the necessary certification for bulk supplies.

Working with an established company gives you confidence in the reliability of the pipes, ensuring they meet the specifications required for your projects. Whether you are in need of a small batch or bulk quantities, choosing the right manufacturer ensures that you receive products that not only meet industry standards but also offer competitive pricing and on-time delivery.

Conclusion

In summary, carbon steel seamless pipes under API 5L X56N offer a combination of strength, durability, and versatility that makes them ideal for use in high-pressure and high-temperature applications, especially in the oil and gas industry. Their seamless construction and ability to withstand extreme conditions make them a preferred choice for manufacturers and companies involved in large-scale pipeline projects.

When selecting a supplier for these pipes, ensure that you choose a manufacturer with a proven track record in bulk production and quality control. This guarantees that you receive carbon steel seamless pipes that meet the necessary standards, providing long-term performance and reliability in your applications.

For those looking for carbon steel seamless pipe manufacturers or need to make a bulk supply purchase, it is important to work with companies that can provide the necessary production capacity, certifications, and technical support to meet your needs.

References

GB/T 7714:Krauss G. Steels: heat treatment and processing principles[J]. (No Title), 1989.

MLA:Krauss, George. "Steels: heat treatment and processing principles." (No Title) (1989).

APA:Krauss, G. (1989). Steels: heat treatment and processing principles. (No Title).