Introduction to Carbon Steel Pipe

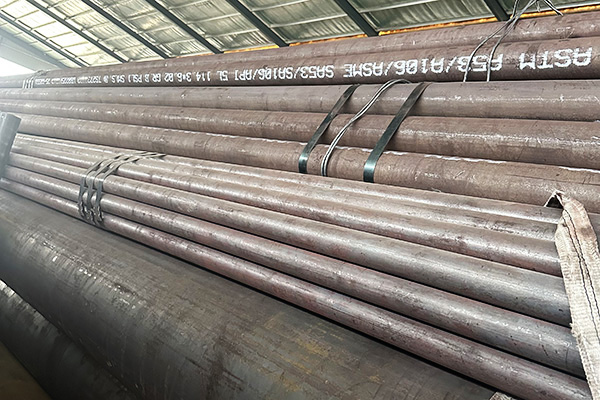

Across global industries, Carbon Steel Pipe has earned recognition as a reliable and versatile material. Its unique blend of strength, affordability, and adaptability makes it essential for critical sectors such as oil and gas, water supply, and building construction. Manufactured under widely accepted specifications like API 5L and offered in grades such as BN, this type of steel pipe provides a long-lasting and cost-effective option for projects requiring both performance and consistency.

Different Types of Carbon Steel Pipe

Carbon Steel Pipe is available in a variety of forms to suit diverse applications:

Seamless Pipe – Produced without welded joints, offering excellent integrity under pressure.

Welded Pipe – Fabricated by welding processes such as ERW or SAW, commonly used in larger-diameter applications.

Galvanized Pipe – Coated with zinc for improved resistance against rust and corrosion.

Hot-Rolled and Cold-Drawn Options – Chosen based on required strength, surface finish, and project specifications.

This variety ensures engineers can select the right pipe type to balance cost, strength, and performance needs.

The Role of API 5L Standards

The API 5L standard serves as a benchmark for Carbon Steel Pipe, particularly in energy-related projects. It defines technical requirements for chemical composition, mechanical strength, dimensional accuracy, and mandatory tests.

Key Advantages of API 5L Certification:

International Acceptance – Ensures compatibility with global construction and energy projects.

Enhanced Quality Control – Regulates allowable chemical elements for predictable material behavior.

Thorough Testing – Covers hydrostatic, impact, and non-destructive examinations for safety assurance.

Reliability in Service – Confirms performance under pressure, making it trusted for oil, gas, and water pipelines.

With API 5L compliance, Carbon Steel Pipe consistently meets the rigorous demands of industrial pipelines.

BN Material and Mechanical Grades

Among the recognized material grades, BN Carbon Steel Pipe stands out for its mechanical balance and versatility.

Properties of BN Grade:

Strong Performance – Provides dependable tensile strength and pressure-handling capability.

Workability – Easy to cut, weld, and assemble during installation.

Durability – Maintains reliability under temperature shifts and demanding operating conditions.

API 5L Alignment – Fully compatible with the requirements outlined in the international standard.

By combining BN material with API 5L compliance, Carbon Steel Pipe ensures a dependable foundation for both energy and structural applications.

Major Applications of Carbon Steel Pipe

The adaptability of Carbon Steel Pipe allows it to be applied in numerous industries:

Oil and Gas Pipelines – Transporting crude oil, refined fuels, and natural gas.

Power Generation – Serving critical functions in thermal, nuclear, and renewable facilities.

Municipal Water Systems – Distributing clean water or managing wastewater.

Construction Sector – Reinforcing buildings, frameworks, and scaffolding.

Industrial Processing – Supporting chemical and petrochemical transport needs.

Its flexibility across applications demonstrates why Carbon Steel Pipe continues to be a cornerstone of modern infrastructure.

Why Choose Carbon Steel Pipe?

The enduring demand for Carbon Steel Pipe stems from its combination of performance and value:

Cost-Effective Strength – Offers a favorable strength-to-cost ratio compared to alternative materials.

High Mechanical Reliability – Withstands elevated pressure and temperature environments.

Long Service Life – Resists fatigue, corrosion (with protective coatings), and mechanical wear.

Sustainability – Steel is fully recyclable, making it environmentally responsible.

Global Standardization – Widely accepted due to API 5L specifications, simplifying international procurement.

These benefits confirm why it is one of the most trusted pipeline materials worldwide.

Ensuring Longevity Through Maintenance

Proper maintenance practices help extend the life of Carbon Steel Pipe:

Scheduled Inspections – Detecting early signs of thinning or corrosion.

Protective Coatings – Adding zinc, epoxy, or paint to safeguard against environmental damage.

Pressure Verification – Routine tests to confirm operational safety.

Replacement Cycles – Updating aged sections to maintain system reliability.

With these steps, Carbon Steel Pipe can provide decades of dependable service in even the most demanding industries.

Conclusion

From large-scale energy networks to vital building projects, Carbon Steel Pipe continues to play a central role in global infrastructure. With its API 5L certification and reliable BN material grade, it combines strength, adaptability, and cost-effectiveness. Its proven performance makes it indispensable for projects that demand resilience and long-term efficiency.

As industries grow and infrastructure expands, Carbon Steel Pipe remains at the forefront—trusted for its durability, mechanical reliability, and ability to meet modern engineering challenges.

References

GB/T 7714:Bai Q, Bai Y. Subsea pipeline design, analysis, and installation[M]. gulf professional publishing, 2014.

MLA:Bai, Qiang, and Yong Bai. Subsea pipeline design, analysis, and installation. gulf professional publishing, 2014.

APA:Bai, Q., & Bai, Y. (2014). Subsea pipeline design, analysis, and installation. gulf professional publishing.