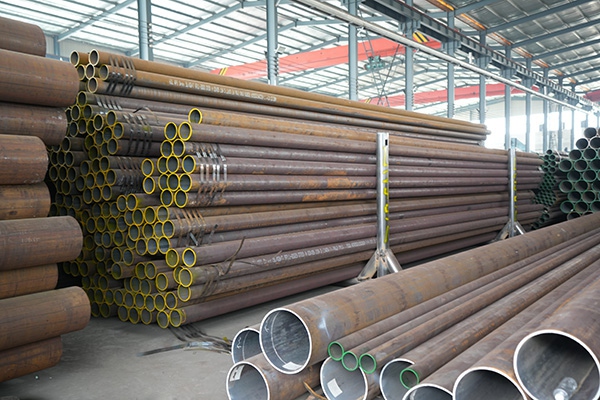

API 5L X52 Refinery Piping Tube

API 5L X52 Refinery Piping Tube is a high-strength carbon steel pipe designed specifically for demanding refinery applications. Manufactured according to the API 5L specification , Grade X52 piping tubes deliver exceptional mechanical prope...

API 5L X52 Refinery Piping Tube is a high-strength carbon steel pipe designed specifically for demanding refinery applications. Manufactured according to the API 5L specification, Grade X52 piping tubes deliver exceptional mechanical properties and superior durability required in harsh refining environments where resistance to pressure, temperature fluctuations, and corrosive substances is critical.

This pipe grade, with a minimum yield strength of 52,000 psi (approximately 360 MPa), provides enhanced strength and toughness, making it ideal for medium- to high-pressure piping systems in refineries, petrochemical plants, and other industrial facilities.

Material Composition and Manufacturing Process

API 5L X52 pipes are produced using controlled carbon steel alloys with precise chemical compositions that include carbon, manganese, phosphorus, sulfur, and other trace elements. The steel is processed through seamless or welded methods such as ERW (Electric Resistance Welding), LSAW (Longitudinal Submerged Arc Welding), or SSAW (Spiral Submerged Arc Welding), ensuring consistent quality and structural integrity.

The manufacturing process often involves heat treatment steps like normalizing or quenching and tempering to optimize mechanical performance, grain structure, and toughness. This results in a piping tube that withstands the complex stressors found in refinery systems.

Mechanical Properties

Minimum Yield Strength: 52,000 psi (360 MPa)

Minimum Tensile Strength: Typically between 70,000 to 90,000 psi (485–620 MPa)

High Impact Toughness: Provides excellent resistance to cracking and brittle failure

Good Ductility and Elongation: Supports flexibility and durability under pressure and thermal cycling

Excellent Weldability: Compatible with various welding techniques, facilitating onsite fabrication and repairs

Key Features

High-Strength Performance: Ideal for refinery piping systems subjected to high pressure and thermal stress.

Corrosion and Heat Resistance: Capable of withstanding corrosive environments and temperature variations typical in refining processes.

Seamless and Welded Options: Versatile manufacturing methods to meet specific project and installation requirements.

Precision Dimensions: Manufactured to strict tolerances to ensure proper fit and fluid flow efficiency.

Surface Protection: Available with coatings such as black paint, epoxy, galvanization, or advanced multilayer coatings to enhance service life.

Applications

API 5L X52 Refinery Piping Tubes are extensively used in:

Crude oil and refined product transport within refineries

High-pressure process piping systems

Petrochemical plants and chemical processing facilities

Steam and gas lines in power and heating plants

Offshore and onshore refinery infrastructure

Pressure vessels and heat exchangers requiring durable piping solutions

Product Specifications

Diameter Range: Typically from 1/2 inch to 48 inches, customizable per project

Wall Thickness: Available in SCH10 to SCH160, XXS, or project-specific thickness

Lengths: Single random length (SRL), double random length (DRL), or cut-to-length options

End Finishes: Plain end (PE), beveled end (BE), threaded end (TE), or customer-specific

Surface Treatment: Black painting, galvanization, epoxy coatings, 3PE/3LPE multilayer coatings, or other specialized finishes

Quality Assurance and Testing

To guarantee reliability and compliance, each API 5L X52 pipe undergoes:

Hydrostatic pressure testing

Non-destructive testing (NDT) including ultrasonic testing (UT), radiographic testing (RT), and magnetic particle inspection (MPI)

Mechanical tests for tensile strength, impact toughness, bend, and hardness

Chemical composition analysis to meet API 5L standards

Dimensional and visual inspections for accuracy and defect prevention

Certification by accredited third-party inspection agencies such as SGS, BV, Lloyd’s Register, or TUV available upon request

Why Choose API 5L X52 Refinery Piping Tube?

API 5L Grade X52 piping tubes offer an optimal balance of strength, toughness, and corrosion resistance needed for refinery and petrochemical piping systems. Their compliance with international standards, combined with rigorous quality control, ensures durability and safety in the most demanding industrial environments.