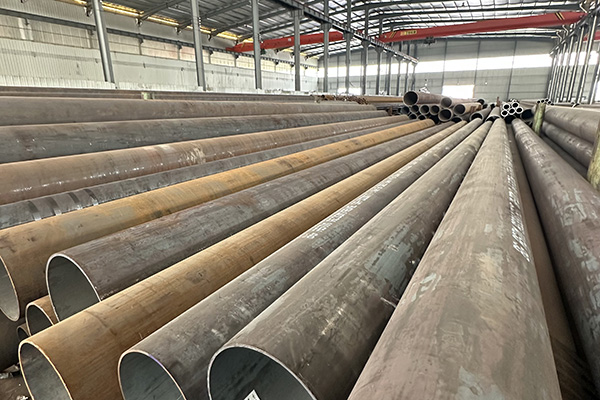

API 5L X70 Refinery Pipeline Tube

API 5L X70 Refinery Pipeline Tube is a high-strength, low-alloy carbon steel pipe engineered for transporting oil, gas, and refined products under high-pressure conditions in refinery and petrochemical environments. Manufactured according t...

API 5L X70 Refinery Pipeline Tube is a high-strength, low-alloy carbon steel pipe engineered for transporting oil, gas, and refined products under high-pressure conditions in refinery and petrochemical environments. Manufactured according to the API 5L specification, Grade X70 indicates a minimum yield strength of 70,000 psi (485 MPa), making it an excellent choice for long-distance, high-capacity transmission lines within and around refineries.

Produced in both seamless and welded forms, API 5L X70 tubing offers exceptional strength-to-weight ratio, corrosion resistance, and fracture toughness. These properties make it ideal for pipeline applications that involve elevated temperatures, internal pressure, or exposure to aggressive media such as hydrogen sulfide (H₂S), carbon dioxide (CO₂), or saline moisture.

The chemical composition typically includes carbon, manganese, phosphorus, sulfur, silicon, and trace elements such as niobium, vanadium, or titanium to enhance strength and low-temperature toughness. For refinery operations, the pipe can be further enhanced with anti-corrosion coatings (such as FBE or 3LPE) and internal linings depending on service conditions.

Key mechanical properties:

Minimum yield strength: 485 MPa (70,000 psi)

Minimum tensile strength: 570–760 MPa

High fracture resistance and fatigue strength

Good weldability and resistance to hydrogen-induced cracking

Typical refinery applications include:

Crude oil and product pipeline systems

High-pressure hydrocarbon transmission within process units

Hydrogen, steam, and water transport lines

Sour service and desulfurization units

Offsite pipeline networks feeding into refinery terminals

API 5L X70 Refinery Pipeline Tubes are available in a wide range of sizes from 2 inches to 48 inches in outer diameter, with wall thicknesses according to standard or custom specifications (e.g., SCH40, SCH80, SCH160). Pipe ends are provided as plain-end (PE), beveled-end (BE), or threaded-end (TE), depending on project requirements.

Each pipe undergoes comprehensive quality control testing, including hydrostatic pressure testing, ultrasonic or radiographic inspection, Charpy V-notch impact testing, hardness evaluation, and full chemical analysis. Compliance with API 5L PSL1 or PSL2 standards ensures suitability for both general and critical refinery operations. Third-party inspections and certificates (SGS, BV, TUV) are available on request.

In summary, API 5L X70 Refinery Pipeline Tube delivers superior strength, reliability, and corrosion resistance for high-pressure pipeline networks in refining and petrochemical facilities. Its mechanical durability and compliance with international standards make it a preferred solution for modern refinery infrastructure where safety and performance are essential.