Across global industries, the search for dependable piping materials continues to be a priority. Among the available choices, Carbon Steel Seamless Pipe manufactured under API 5L X56N specifications has become indispensable. Its unique properties ensure reliable performance in environments where failure is not an option, such as chemical plants and gas pipeline systems. With China manufacturers offering batch supply, companies worldwide can secure both consistent quality and competitive pricing.

The Structural Advantage of Seamless Design

The term “seamless” highlights the absence of welding joints, which are often the weakest points in a pipeline. This design significantly enhances durability, allowing API 5L X56N carbon steel seamless pipes to withstand heavy internal pressure and fluctuating temperatures.

Seamless pipes also maintain uniform wall thickness, providing:

·Superior resistance to cracking.

·Improved performance under stress.

·Longer service life compared with welded alternatives.

For industries requiring uninterrupted flow of critical fluids, these qualities are essential.

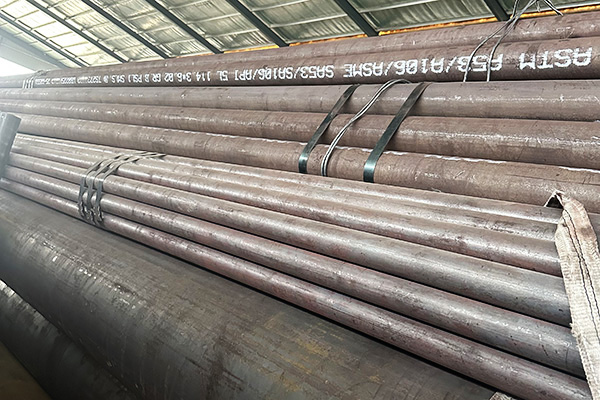

Reliability Through API 5L X56N Standards

The API 5L specification, particularly the X56N grade, sets high benchmarks for material integrity.

Adherence to this standard guarantees:

·Mechanical strength suitable for demanding operations.

·Consistent dimensional tolerances for precise fitting.

·Compatibility with international pipeline infrastructure.

By following strict inspection and testing procedures, manufacturers ensure pipes meet the safety and reliability expectations of modern projects.

Applications in Chemical and Gas Pipeline Transport

The versatility of Carbon Steel Seamless Pipe makes it a cornerstone of various industries. Its most significant roles include:

·Chemical Industry: Seamless pipes resist corrosive fluids, supporting safe and efficient chemical processing.

·Gas Transmission: Long-distance and high-pressure gas pipelines rely on seamless pipes for structural stability.

·Industrial Energy Projects: Facilities handling oil and by-products use API 5L X56N pipes to maintain secure operations.

In each of these cases, seamless pipes protect against leaks and failures, ensuring smooth, safe, and efficient transport.

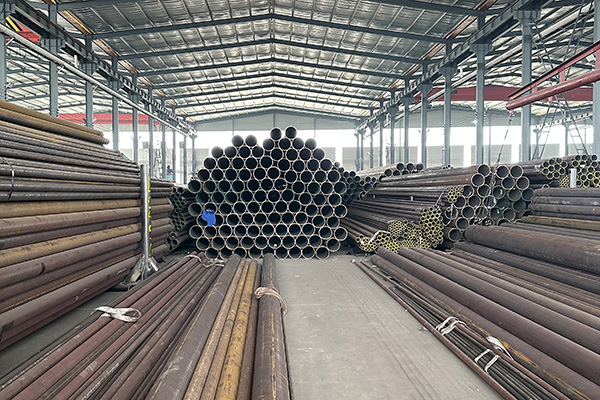

Supply Benefits from China Manufacturers

Sourcing directly from China suppliers provides a strategic advantage for international buyers:

1.Batch Supply Availability – Large production capacity ensures projects can be supplied in volume without delays.

2.Cost Efficiency – Competitive pricing makes procurement more affordable without compromising standards.

3.Quality Assurance – Certified facilities follow API guidelines, maintaining product consistency.

These benefits make China manufacturers of carbon steel seamless pipes reliable partners for global infrastructure projects.

Why Seamless Pipes Outperform Welded Alternatives

While welded pipes remain an option for less demanding applications, seamless pipes offer significant advantages:

·No weld seam eliminates weak points.

·Higher reliability in high-pressure operations.

·Better performance in corrosive or aggressive environments.

For industries like chemical processing and gas transport, where safety and continuity are critical, Carbon Steel Seamless Pipe API 5L X56N is the superior choice.

Long-Term Economic Value

Although initial costs for seamless pipes may be slightly higher, they deliver substantial long-term value:

·Reduced downtime from fewer failures.

·Lower maintenance expenses.

·Extended operational lifespan.

This makes Carbon Steel Seamless Pipe not only a technical asset but also a cost-effective investment.

Conclusion

The role of Carbon Steel Seamless Pipe manufactured under API 5L X56N standards is irreplaceable in today’s industrial landscape. From chemical processing to gas pipeline transport, its durability and reliability ensure safety and efficiency.

With China manufacturers offering batch supply, industries gain access to high-quality materials backed by global standards and competitive pricing. Choosing seamless pipes for critical projects means investing in long-term stability, efficiency, and operational safety.

For enterprises seeking proven performance, Carbon Steel Seamless Pipe API 5L X56N remains the trusted solution.

References

GB/T 7714:Mammadov A, Babayev A, Ismayilov N, et al. Improvement of Production Processes of Seamless Steel Pipes for Oil and Gas Production[J]. Key Engineering Materials, 2024, 979: 63-71.

MLA:Mammadov, Arif, et al. "Improvement of Production Processes of Seamless Steel Pipes for Oil and Gas Production." Key Engineering Materials 979 (2024): 63-71.

APA:Mammadov, A., Babayev, A., Ismayilov, N., Huseynov, M., & Guliyev, F. (2024). Improvement of Production Processes of Seamless Steel Pipes for Oil and Gas Production. Key Engineering Materials, 979, 63-71.