Why API 5L X65 Oil and Gas Line Pipe Matters

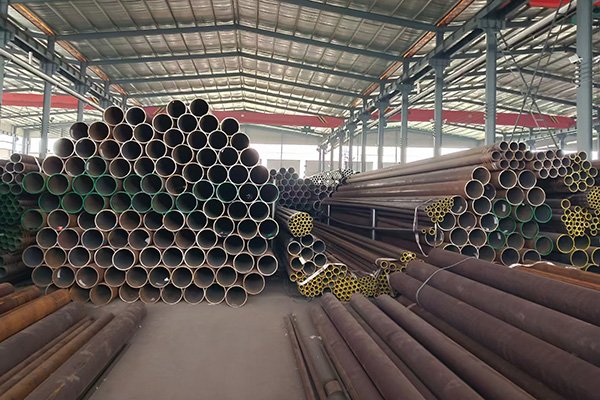

When discussing long-distance energy transportation, Oil and Gas Line Pipe plays a decisive role in safety, efficiency, and long-term reliability. Among various material grades defined by international standards, API 5L X65 Oil and Gas Line Pipe stands out as a widely adopted solution for demanding pipeline projects.

From upstream extraction to cross-regional transmission networks, this grade has proven its value through balanced strength, toughness, and weldability. Backed by controlled manufacturer-level production systems and stable bulk supply capabilities, API 5L X65 has become a trusted option for modern oil and gas infrastructure.

Understanding API 5L and the X65 Grade

API 5L is a specification issued to regulate the quality and performance of line pipe used in petroleum and natural gas transportation systems. Within this framework, X65 represents a specific minimum yield strength level, making it suitable for medium- to high-pressure applications.

Oil and Gas Line Pipe produced under API 5L X65 requirements must meet strict criteria related to chemical composition, mechanical performance, dimensional tolerances, and inspection procedures. These controls ensure consistency across large production batches, which is critical for pipeline projects that require uniform behavior over long distances.

Material Composition and Mechanical Performance

API 5L X65 Oil and Gas Line Pipe is engineered to achieve a balance between strength and ductility. Its alloy design allows the pipe to withstand high internal pressure while maintaining resistance to cracking and deformation under external stress.

From an engineering perspective, this balance is essential for pipelines exposed to varying temperatures, soil conditions, and operational loads. Properly controlled production ensures that each pipe section delivers predictable mechanical behavior, reducing the risk of weak points across the transmission system.

Manufacturing Process of API 5L X65 Oil and Gas Line Pipe

The manufacturing process is a critical factor in defining the reliability of Oil and Gas Line Pipe. API 5L X65 pipes are produced through tightly monitored forming, heat treatment, and finishing stages designed to achieve consistent microstructure and performance.

Advanced production lines emphasize dimensional accuracy, surface integrity, and metallurgical stability. For large pipeline projects, manufacturer-controlled production environments ensure that bulk orders meet the same technical benchmarks from the first pipe to the last.

Quality Control and Inspection Standards

Quality assurance is a defining characteristic of API 5L X65 Oil and Gas Line Pipe. Each production batch undergoes multiple inspection stages, including dimensional checks, mechanical testing, and non-destructive examination.

These inspections verify compliance with API 5L requirements and confirm that the pipe can perform reliably in real-world pipeline environments. Traceability systems further support project confidence by linking each pipe back to its production data, a key requirement for large-scale oil and gas developments.

Typical Applications in Oil and Gas Transmission

API 5L X65 Oil and Gas Line Pipe is widely used in both onshore and offshore transmission systems. Its strength-to-weight ratio allows for efficient transportation of hydrocarbons while maintaining structural integrity under operational pressure.

In long-distance pipelines, this grade supports reduced wall thickness without compromising safety, helping project owners optimize material usage and installation efficiency. These advantages make X65 a practical choice for energy transmission networks that demand both performance and cost control.

Advantages Over Lower-Grade Line Pipe

Compared with lower-strength grades, API 5L X65 Oil and Gas Line Pipe offers improved pressure handling and better resistance to operational fatigue. This translates into longer service life and reduced maintenance requirements over the pipeline’s operational cycle.

For projects requiring stable performance over decades, the consistency achieved through controlled production and standardized inspection provides an added layer of confidence, particularly when sourcing pipes in bulk quantities.

Role of Production Consistency in Long-Term Reliability

Production consistency directly influences the reliability of Oil and Gas Line Pipe. Variations in material properties or dimensional accuracy can introduce stress concentration points within a pipeline system.

That is why large infrastructure projects prioritize suppliers with proven production capacity and batch consistency, ensuring that every delivered pipe performs as expected throughout the system.

Conclusion: Why API 5L X65 Oil and Gas Line Pipe Is a Trusted Choice

So, what is API 5L X65 Oil and Gas Line Pipe? It is a carefully engineered pipeline material designed to meet the technical, operational, and safety demands of modern oil and gas transmission.

Supported by standardized manufacturing, strict inspection protocols, and reliable manufacturer-backed bulk supply, API 5L X65 Oil and Gas Line Pipe continues to serve as a cornerstone material for energy infrastructure projects worldwide.

References

GB/T 7714:Wenman T, Dim J. Pipeline integrity management[C]//Abu Dhabi International Petroleum Exhibition and Conference. SPE, 2012: SPE-161948-MS.

MLA:Wenman, Tim, and Joe Dim. "Pipeline integrity management." Abu Dhabi International Petroleum Exhibition and Conference. SPE, 2012.

APA:Wenman, T., & Dim, J. (2012, November). Pipeline integrity management. In Abu Dhabi International Petroleum Exhibition and Conference (pp. SPE-161948). SPE.