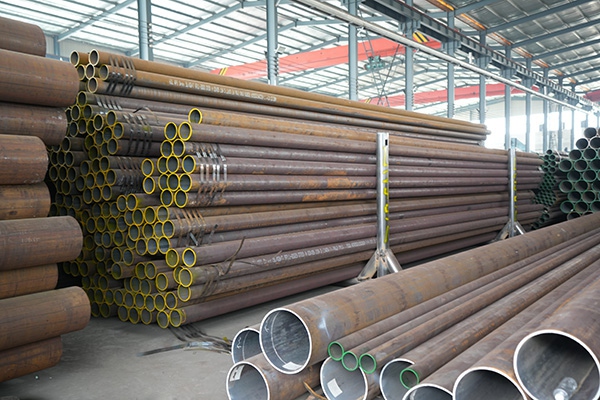

Refinery Piping Tubes as the Industry Backbone

Every refinery relies on a solid network of piping to keep operations running smoothly. At the center of these systems is the refinery piping tube, responsible for transporting crude, gas, and processed fuels under extreme conditions.

To guarantee both safety and efficiency, international standards such as API 5L are followed. Among its grades, X52 has become a preferred option for its balance of strength, corrosion resistance, and cost-effectiveness. For large-scale projects, choosing a China-based supplier capable of bulk supply ensures timely delivery and consistent quality.

API 5L and X52: The Foundation of Quality Tubes

API 5L Standard

The API 5L specification governs the production of steel line pipes used in natural gas and petroleum transport. It defines mechanical properties, chemical composition, and testing requirements that make piping tubes suitable for critical industrial use.

X52 Material Benefits

The X52 grade within API 5L has proven especially effective for refinery piping:

·Withstands high pressures and mechanical loads.

·Excellent weldability for fabrication and installation.

·Resistant to chemical attack from hydrocarbons and refinery by-products.

·Delivers dependable service life in both onshore and offshore projects.

This makes API 5L X52 an industry standard for refining and pipeline operations.

Where Refinery Piping Tubes Are Used

1.Process Flow Systems – Carrying feedstocks, crude oil, and refined fuels between refinery units.

2.Heat and Distillation Units – Handling elevated temperatures in columns, heaters, and reactors.

3.Cryogenic Services – Paired with cryogenic alloy pipes in liquefied gas applications.

4.LNG Transport – Complementing LNG pipeline alloy pipes to deliver natural gas securely.

5.Critical Junctions – Used for valves, fittings, and control stations where reliability is essential.

Key Advantages of API 5L X52 Refinery Tubes

·Strength & Durability – Resistant to corrosion, wear, and mechanical stress.

·Safety Across Conditions – Performs well under both hot and sub-zero temperatures.

·Operational Efficiency – Reduces risk of leakage or shutdown.

·Compliance – Meets global standards like API, ASTM, and ASME.

·Scalable Supply – A Chinese manufacturer with bulk capacity can fulfill even the largest orders.

Best Practices for Maintenance

To keep refinery piping tubes operating at peak performance:

·Routine Inspections – Visual, ultrasonic, or radiographic checks for thinning or cracks.

·Pressure Verification – Testing to confirm compliance with design limits.

·Temperature Control – Monitoring to avoid thermal expansion issues.

·Documentation – Keeping traceable records of API 5L certification and inspection logs.

Why Work with Chinese Suppliers

Large-scale refinery and pipeline projects often demand not just quality, but volume. Partnering with a China supplier brings distinct advantages:

·Proven adherence to API 5L X52 specifications.

·Ability to customize thicknesses and diameters for project needs.

·Bulk production and supply, a clear marker of manufacturer reliability.

·Competitive cost without compromising quality standards.

For international oil and gas projects, these capabilities make Chinese manufacturers a preferred choice.

Conclusion

The refinery piping tube remains a critical part of modern energy infrastructure, ensuring the safe and efficient transfer of fluids in complex refinery systems. With API 5L compliance and the dependable performance of X52 grade steel, these tubes deliver the durability and safety that today’s oil and gas projects require.

By sourcing from a Chinese manufacturer with bulk supply capabilities, refineries and pipeline operators can secure both quality and consistency. For projects focused on long-term safety and operational success, refinery piping tubes are an essential investment.

References

GB/T 7714:Abdu M T, Khalifa W, Abdelrahman M S. Investigation of erosion-corrosion failure of API X52 carbon steel pipeline[J]. Scientific Reports, 2023, 13(1): 20494.

MLA:Abdu, Mahmoud T., Waleed Khalifa, and Maiada S. Abdelrahman. "Investigation of erosion-corrosion failure of API X52 carbon steel pipeline." Scientific Reports 13.1 (2023): 20494.

APA:Abdu, M. T., Khalifa, W., & Abdelrahman, M. S. (2023). Investigation of erosion-corrosion failure of API X52 carbon steel pipeline. Scientific Reports, 13(1), 20494.