The foundation of modern industrial systems depends on the integrity of their piping networks. Among them, the Pressure Seamless Pipe plays a crucial role—engineered to perform under extreme temperature, high pressure, and corrosive operating environments.

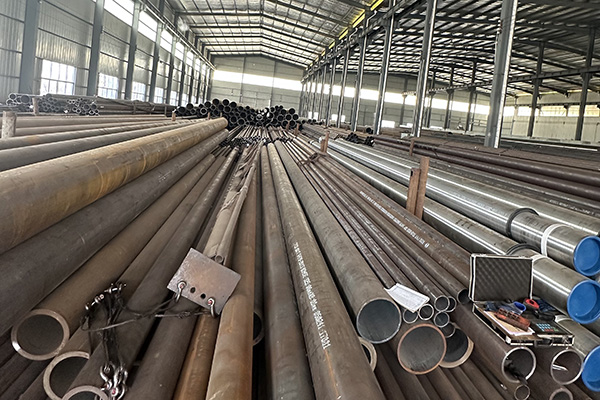

Unlike welded pipes, seamless pipes are produced without joints, giving them superior tensile strength, durability, and pressure resistance. With the rising demand for reliable infrastructure, China manufacturers have become global leaders, offering bulk supply of high-grade pressure seamless pipes that comply with international standards and performance expectations.

1. What Defines a Pressure Seamless Pipe

A Pressure Seamless Pipe is a cylindrical steel component crafted for transporting liquids and gases under sustained internal pressure. Its seamless construction ensures continuous metal grain flow, removing the weak spots typically found in welded alternatives.

Core Advantages Include:

Uniform mechanical strength across the full length

Excellent tolerance to high stress and cyclic loading

Smooth internal surface for efficient fluid transfer

High temperature and corrosion resistance

These properties make seamless pipes a preferred choice across industries where safety and long-term stability are non-negotiable.

2. Standard Specifications and Material Grades

The quality of a Pressure Seamless Pipe is governed by its material composition and adherence to international manufacturing codes.

Common Standards:

ASTM A106 / A53: Widely used for high-pressure and high-temperature service

API 5L: Designed for oil, natural gas, and petroleum pipelines

EN 10216: European specifications for seamless pressure pipe applications

ASME SA335 / SA106: For boiler and power plant operations

Typical Material Grades:

Carbon steel (GR.B / GR.C): Ideal for moderate pressure systems

Alloy steel (T11 / T22): Suited for high-temperature or cyclic environments

Stainless steel (304 / 316): Preferred for chemical or corrosive media

These materials are carefully heat-treated to balance strength, ductility, and resistance to pressure deformation.

3. Manufacturing Process: How Precision Creates Strength

The process of producing Pressure Seamless Pipe involves multiple high-precision stages designed to maintain metal uniformity and eliminate microstructural defects.

Production Workflow:

Steel Billet Selection: Only pure, defect-free billets with fine-grain structure are used.

Hot Piercing: Heated billets are pierced using rotary or extrusion methods to form hollow tubes.

Mandrel or Plug Rolling: The hollow billet is rolled and elongated to specific dimensions.

Heat Treatment: Normalizing, quenching, and tempering enhance grain structure and stress resistance.

Finishing and Inspection: Pipes are straightened, sized, and undergo surface finishing.

Modern China manufacturers employ digital controls and automated inspection systems to ensure that every pipe produced in bulk supply meets precise dimensional and metallurgical standards.

4. Core Industrial Applications

a. Oil and Gas Transport

In both upstream and downstream operations, Pressure Seamless Pipe is indispensable. It transports crude oil, refined fuels, and natural gas while withstanding constant vibration, pressure pulsation, and chemical exposure.

b. Thermal and Nuclear Power

Power plants rely heavily on seamless pipes for steam lines, reheaters, and boiler feed systems. Their ability to operate under high temperature and pressure ensures consistent performance and minimal downtime.

c. Petrochemical Refineries

Refining processes involve highly reactive substances under pressure. Seamless pipes prevent leaks, maintain material purity, and resist cracking caused by thermal expansion or corrosion.

d. Heavy Machinery and Hydraulic Systems

In manufacturing and automation, high-pressure pipes are crucial for hydraulic cylinders, compressors, and process lines that require reliability under fluctuating loads.

e. Marine and Offshore Platforms

Saltwater exposure and dynamic pressure cycles make seamless pipes the preferred solution for offshore pipelines and marine engineering applications.

5. Testing and Quality Assurance

The reliability of a Pressure Seamless Pipe depends on rigorous inspection from raw material to final product.

Essential Testing Methods:

Hydrostatic Pressure Test: Verifies resistance to internal pressure and leakage.

Ultrasonic and Eddy Current Tests: Detect internal or surface flaws without damaging the pipe.

Dimensional Accuracy Inspection: Ensures wall thickness and diameter consistency.

Tensile and Flattening Tests: Assess strength and ductility under stress.

These procedures confirm that each pipe can handle the design pressure without deformation or rupture, even in extreme service conditions.

6. Surface Protection and Longevity

Because Pressure Seamless Pipe often operates in corrosive or humid environments, surface treatments are vital to extend service life.

Common Treatments Include:

Pickling and Oiling: Cleans scale and prevents oxidation during transport.

Phosphate Coating: Adds an anti-corrosion layer.

Epoxy or Zinc Coating: Enhances resistance to chemical and saltwater corrosion.

These processes help maintain performance stability in pipelines used across power plants, refineries, and offshore installations.

7. China Manufacturers and Global Bulk Supply

The global demand for Pressure Seamless Pipe has led to significant investment in production technology among China manufacturers. With integrated heat treatment lines, advanced testing laboratories, and efficient logistics, they have become trusted partners for large-scale industrial projects.

Advantages of Working with China Suppliers:

Proven bulk supply capabilities for multi-sector demand

Compliance with API, ASTM, and EN standards

Competitive pricing with strong technical support

Flexible customization for alloy composition and size

These factors make China a strategic source for businesses seeking reliability, quality assurance, and fast turnaround times.

8. Maintenance and Operational Monitoring

Even the strongest pipes require proper inspection to maintain system safety and efficiency.

Best Practices:

Conduct regular wall thickness measurements to detect early corrosion

Perform pressure tests during maintenance cycles

Use thermal imaging to identify hotspots

Schedule cleaning and descaling operations to improve heat transfer efficiency

Routine checks and data logging help predict service life and reduce the risk of pipeline failure.

Conclusion

The Pressure Seamless Pipe is a cornerstone of modern industrial engineering, providing unmatched strength, precision, and resistance in high-pressure systems.

Partnering with a China manufacturer that offers bulk supply of certified seamless pipes ensures stable performance, cost efficiency, and adherence to global quality standards.

As industries continue to pursue higher productivity and sustainability, the role of reliable Pressure Seamless Pipe solutions will remain central—supporting energy, manufacturing, and petrochemical systems that power the world.

References

GB/T 7714:Utomo F F, Rashyid M I, Nugraha A D, et al. A RECENT REVIEW ON THE FAILURE ANALYSIS OF BOILER TUBE[J]. Jurnal Rekayasa Mesin, 2024, 15(2): 619-646.

MLA:Utomo, Faris Fadhil, et al. "A RECENT REVIEW ON THE FAILURE ANALYSIS OF BOILER TUBE." Jurnal Rekayasa Mesin 15.2 (2024): 619-646.

APA:Utomo, F. F., Rashyid, M. I., Nugraha, A. D., & Muflikhun, M. A. (2024). A RECENT REVIEW ON THE FAILURE ANALYSIS OF BOILER TUBE. Jurnal Rekayasa Mesin, 15(2), 619-646.