Constructing a Crude Oil Pipeline requires careful planning, precision engineering, and strict adherence to industry standards. Pipelines transport crude oil over long distances, often through complex terrains, while maintaining safety and operational efficiency. A well-constructed pipeline not only ensures smooth transportation but also reduces environmental risks and maintenance costs.

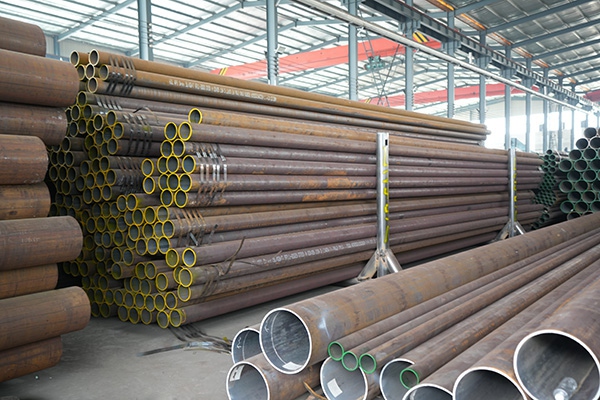

China factory manufacturers are now key contributors in supplying bulk pipeline materials, offering high-quality, standardized products that meet the demanding needs of international oil and gas projects.

1. Essential Materials for Crude Oil Pipelines

Material selection is the cornerstone of a durable pipeline system. Pipes must resist high internal pressures, temperature fluctuations, and chemical corrosion. Commonly used materials include:

Carbon Steel: Economical and strong, typically compliant with ASTM A106 or API 5L standards.

Alloy Steel: Provides superior strength and thermal resistance for high-pressure applications.

Stainless Steel: Ideal for corrosive environments or offshore pipelines.

Coatings and Linings: Anti-corrosion coatings and internal linings protect pipelines from wear and chemical damage.

China suppliers provide both seamless and welded pipes in various grades, ensuring consistent quality for bulk supply.

2. Welding Practices for Reliable Pipeline Assembly

Proper welding is critical to maintain the structural integrity of a pipeline. Faulty welds can cause leaks, environmental hazards, or catastrophic failures. Common welding techniques include:

Butt Welding

Joins pipe ends with full penetration, creating a seamless connection.

Ensures uniform mechanical strength along the pipeline.

Arc Welding (SMAW, GTAW, GMAW)

Selected based on pipe material, thickness, and environmental factors.

TIG (GTAW) provides precision, while SMAW is widely used for field applications.

Automatic Welding

Enhances weld consistency and reduces human error.

Common in large-scale pipelines requiring bulk welding of multiple sections.

China factory manufacturers also provide pre-fabricated pipe segments and fittings optimized for rapid assembly and consistent weld quality.

3. Inspection and Quality Assurance

Inspection is essential to ensure long-term pipeline performance. Key quality checks include:

Hydrostatic Pressure Testing: Confirms the pipeline can withstand operating pressures.

Non-Destructive Testing (NDT): Radiography, ultrasonic, and magnetic particle inspections detect internal and external flaws.

Dimensional Checks: Ensures pipe diameters, wall thickness, and bevel angles meet specifications.

Corrosion Resistance Evaluation: Verifies coating and lining effectiveness, along with cathodic protection systems.

Inspections align with standards such as API 1104, ASME B31.4, and ISO 3183, guaranteeing reliability. China suppliers often provide inspection certificates and mill test reports for all bulk supply shipments.

4. Construction Considerations

Building a crude oil pipeline involves more than just materials and welding:

Route Planning

Considers terrain, environmental impact, and regulatory compliance.

Optimizes pipeline alignment to minimize risks.

Trenching and Support

Stabilizes the pipeline and prevents excessive stress or bending.

Uses bedding materials and supports to accommodate ground movement.

Environmental and Safety Measures

Includes leak detection, emergency shutoff valves, and spill containment systems.

Complies with environmental protection standards and safety regulations.

Testing and Commissioning

Hydrostatic and NDT testing before commissioning ensures operational readiness.

Monitoring systems track stress, corrosion, and other performance indicators during service.

5. Advantages of China Factory Bulk Supply

Sourcing from China factory manufacturers offers several benefits:

Bulk Supply Capacity: Capable of delivering large volumes for extensive pipeline projects.

Standardized Quality: Pipes comply with ASTM, API, and ISO requirements.

Cost Efficiency: Competitive pricing without compromising performance.

Custom Fabrication: Ability to provide specialized fittings, elbows, and coated pipelines.

These advantages make China suppliers a reliable choice for long-term, large-scale pipeline construction.

6. Emerging Trends in Crude Oil Pipeline Construction

The industry is advancing to meet modern energy demands:

High-Strength, Corrosion-Resistant Materials: Reduces maintenance and increases lifespan.

Automated Welding Systems: Improve efficiency and reduce human error.

Intelligent Monitoring: Sensors provide real-time data on stress, temperature, and leaks.

Sustainable Construction Practices: Emphasize environmentally friendly materials and methods.

China manufacturers are adopting these innovations, ensuring bulk pipeline supply meets the evolving needs of global oil infrastructure.

Conclusion

A Crude Oil Pipeline is a critical infrastructure element, requiring high-quality materials, precise welding, and thorough inspections. By sourcing from China factory suppliers, project managers gain access to certified bulk materials, pre-fabricated segments, and rigorous quality assurance.

With these resources, pipelines are built to last, ensuring safe, efficient, and environmentally responsible transportation of crude oil across challenging terrains. China suppliers continue to provide reliable, cost-effective solutions for large-scale pipeline projects worldwide.

References

GB/T 7714:ASTM A106. Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service[J]. 2020.

MLA:ASTM A106. "Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service." (2020).

APA:ASTM A106. (2020). Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service.