1.Why Buried Line Pipe Matters

A Buried Line Pipe is a critical component in underground pipeline networks that transport crude oil, natural gas, and water across industrial and energy sectors.

Unlike above-ground piping, these lines face challenges such as soil pressure, moisture exposure, and corrosion.

Pipes produced under the API 5L X70Q specification offer exceptional strength, weld integrity, and durability. As a China-based pipeline manufacturer, we focus on engineering buried pipes that meet international safety and performance requirements, ensuring consistent quality for bulk supply projects worldwide.

2. Key Design Aspects of Buried Line Pipelines

2.1 Material and Grade Selection

The API 5L standard defines the technical and mechanical properties of line pipes.

Among its grades, X70Q is known for its high yield strength (≥485 MPa), superior impact resistance, and excellent toughness even in low-temperature conditions.

These properties make it ideal for long-distance buried pipelines that must withstand high internal pressure and external soil loads.

2.2 Structural Dimensions

The pipe’s wall thickness, diameter, and length are determined through detailed engineering calculations.

Designers factor in working pressure, ground movement, and corrosion allowance.

For buried installations, a slightly thicker wall is preferred to increase structural stability and extend service life.

2.3 Welding and Joint Design

Precision welding plays a decisive role in pipeline reliability.

Automated welding techniques—such as submerged arc welding (SAW) and gas metal arc welding (GMAW)—ensure consistent seam quality.

All joints undergo visual inspection, ultrasonic testing, and hydrostatic verification according to API 5L acceptance criteria.

3. Corrosion Protection Strategies

Buried pipelines are constantly exposed to environmental and electrochemical risks.

Effective corrosion prevention combines coating, cathodic protection, and soil management.

3.1 Protective Coating Systems

External coatings are the first defense against corrosion. Common systems include:

·3PE (Three-Layer Polyethylene) coating for superior mechanical and chemical protection

·FBE (Fusion-Bonded Epoxy) for excellent adhesion and high-temperature resistance

·Bituminous coating for cost-effective basic protection

These coatings form a continuous barrier that isolates the steel surface from corrosive elements in the soil.

3.2 Cathodic Protection (CP)

When coating alone is not enough, cathodic protection adds an electrical safeguard.

Two common methods are used:

·Sacrificial anode CP, employing magnesium or zinc

·Impressed current CP, powered by an external DC source

Combining coating and CP minimizes electrochemical corrosion, ensuring that Buried Line Pipes retain integrity over decades of operation.

3.3 Backfill and Soil Conditions

The backfill layer surrounding a buried pipeline must be free of stones or sharp debris that could damage coatings.

Using fine-grained soil or sand improves long-term coating performance and helps distribute soil loads evenly.

4. Inspection and Maintenance Routines

Preventive maintenance is key to safe operation of underground pipeline systems.

4.1 Periodic Inspection

Routine inspections involve:

·In-line inspection (ILI) tools for detecting wall thinning or cracks

·Cathodic protection surveys to monitor electrical potential levels

·Visual and ultrasonic inspections during maintenance shutdowns

Regular testing allows operators to detect early-stage degradation and take corrective action before major damage occurs.

4.2 Cleaning and Internal Efficiency

Pipeline cleaning (pigging) removes sediment, rust, and wax buildup.

This not only improves flow efficiency but also reduces internal corrosion caused by trapped contaminants.

4.3 Repair and Replacement

When defects are identified, repair options include:

·Installing welded sleeves for reinforcement

·Applying composite wraps for small leaks

·Full section replacement in critical areas

All repairs should comply with API 5L and ISO 3183 standards to maintain system integrity and performance.

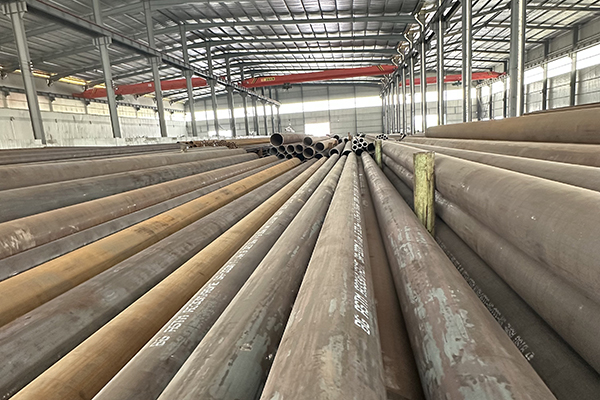

5. Manufacturing and Quality Control

A trusted China Buried Line Pipe supplier follows rigorous manufacturing and testing procedures to guarantee product reliability.

Key quality steps include:

1.Raw material testing and mill certification

2.Dimensional inspection and ovality checks

3.Non-destructive testing (NDT) – ultrasonic and radiographic

4.Hydrostatic pressure testing

5.Coating adhesion and thickness verification

6.Batch traceability with engraved heat numbers

These steps ensure each pipe delivered for buried pipeline projects meets strict API and international quality benchmarks.

6. Environmental and Operational Best Practices

Environmental stewardship is an important aspect of modern pipeline design.

Using eco-friendly coatings and recyclable anode materials helps reduce long-term impact.

Proper burial depth—typically between 0.8 to 1.2 meters—also prevents thermal stress, frost damage, and mechanical impact.

Pipeline operators are encouraged to maintain real-time monitoring systems for pressure, temperature, and leakage detection to ensure 24/7 operational safety.

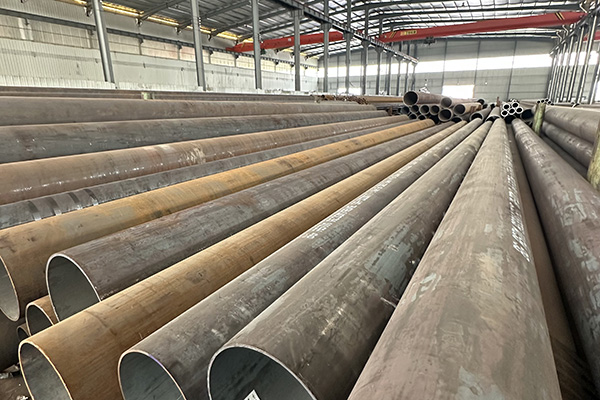

7. Conclusion: Reliable Buried Line Pipe from a Professional China Manufacturer

The reliability of a Buried Line Pipe system depends on sound design, corrosion protection, and disciplined maintenance.

Pipes made from API 5L X70Q steel provide exceptional mechanical strength, pressure resistance, and weld stability for long-distance underground transport.

As a China-based bulk supplier and manufacturer, we specialize in delivering consistent quality, competitive pricing, and dependable lead times.

Our production lines are built for precision and repeatability, ensuring that every buried pipeline project benefits from certified materials and proven performance.

References

GB/T 7714:Nwoye C I, Imamudeen B, Nwambu C N. Analysis of corrosion rate of buried API 5L× 70 steel pipeline in soil by Taguchi technique[J]. Int. Journal of Civil Engineering and Architecture Engineering Vol. 5 (1) P28, 2024, 33.

MLA:Nwoye, C. I., B. Imamudeen, and C. N. Nwambu. "Analysis of corrosion rate of buried API 5L× 70 steel pipeline in soil by Taguchi technique." Int. Journal of Civil Engineering and Architecture Engineering Vol. 5 (1) P28 33 (2024).

APA:Nwoye, C. I., Imamudeen, B., & Nwambu, C. N. (2024). Analysis of corrosion rate of buried API 5L× 70 steel pipeline in soil by Taguchi technique. Int. Journal of Civil Engineering and Architecture Engineering Vol. 5 (1) P28, 33.