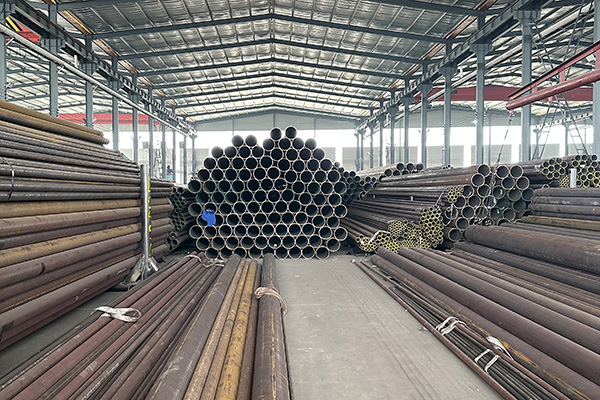

API 5L X56N Carbon Steel Seamless Pipe

API 5L X56N Carbon Steel Seamless Pipe is a high-strength, normalized carbon steel pipe manufactured in accordance with the API 5L specification, designed primarily for transporting oil, gas, and water in demanding pipeline systems. The “...

API 5L X56N Carbon Steel Seamless Pipe is a high-strength, normalized carbon steel pipe manufactured in accordance with the API 5L specification, designed primarily for transporting oil, gas, and water in demanding pipeline systems. The “X56” grade indicates a minimum yield strength of 56,000 psi (386 MPa), while the “N” denotes normalizing heat treatment, which improves the pipe’s structural uniformity, mechanical strength, and resistance to cracking under stress.

Produced through seamless manufacturing processes, this pipe features a uniform wall thickness, smooth internal surface, and no weld seams, ensuring maximum pressure resistance and reliability. Seamless construction significantly reduces the risk of failure in high-pressure and corrosive environments, making it ideal for both onshore and offshore pipeline installations.

The chemical composition of API 5L X56N typically includes carbon, manganese, phosphorus, sulfur, silicon, and microalloying elements such as niobium and vanadium. These elements contribute to increased toughness, fatigue resistance, and improved weldability—key factors for pipelines exposed to fluctuating temperatures and mechanical loads.

Mechanically, API 5L X56N seamless pipes offer an excellent balance of high tensile strength, ductility, and impact toughness, even at lower temperatures. The normalized heat treatment process refines the steel’s grain structure, making it more resistant to crack propagation and suitable for critical service applications.

Typical applications include:

Crude oil and natural gas transmission pipelines

Water injection and disposal systems

High-pressure fluid transport in petrochemical plants

Structural piping in energy and utility sectors

Onshore and offshore pipeline infrastructure

API 5L X56N pipes are available in a wide range of diameters, typically from 2 inches to 48 inches, with wall thicknesses conforming to standard pipe schedules (SCH40, SCH80, SCH160) and customized requirements. Pipe ends can be supplied as plain end (PE), beveled end (BE), or threaded end (TE) depending on the project.

To ensure product reliability and code compliance, API 5L X56N pipes undergo rigorous quality control procedures, including hydrostatic testing, ultrasonic inspection, radiographic testing, Charpy impact tests, and chemical composition analysis. Third-party inspection and certification (e.g., SGS, BV, TUV) are available on request.

In summary, API 5L X56N Carbon Steel Seamless Pipe is a robust, high-performance piping solution for critical fluid transport applications. With its seamless construction, normalized microstructure, and reliable mechanical performance, it is well-suited for use in energy infrastructure projects where safety and efficiency are essential.